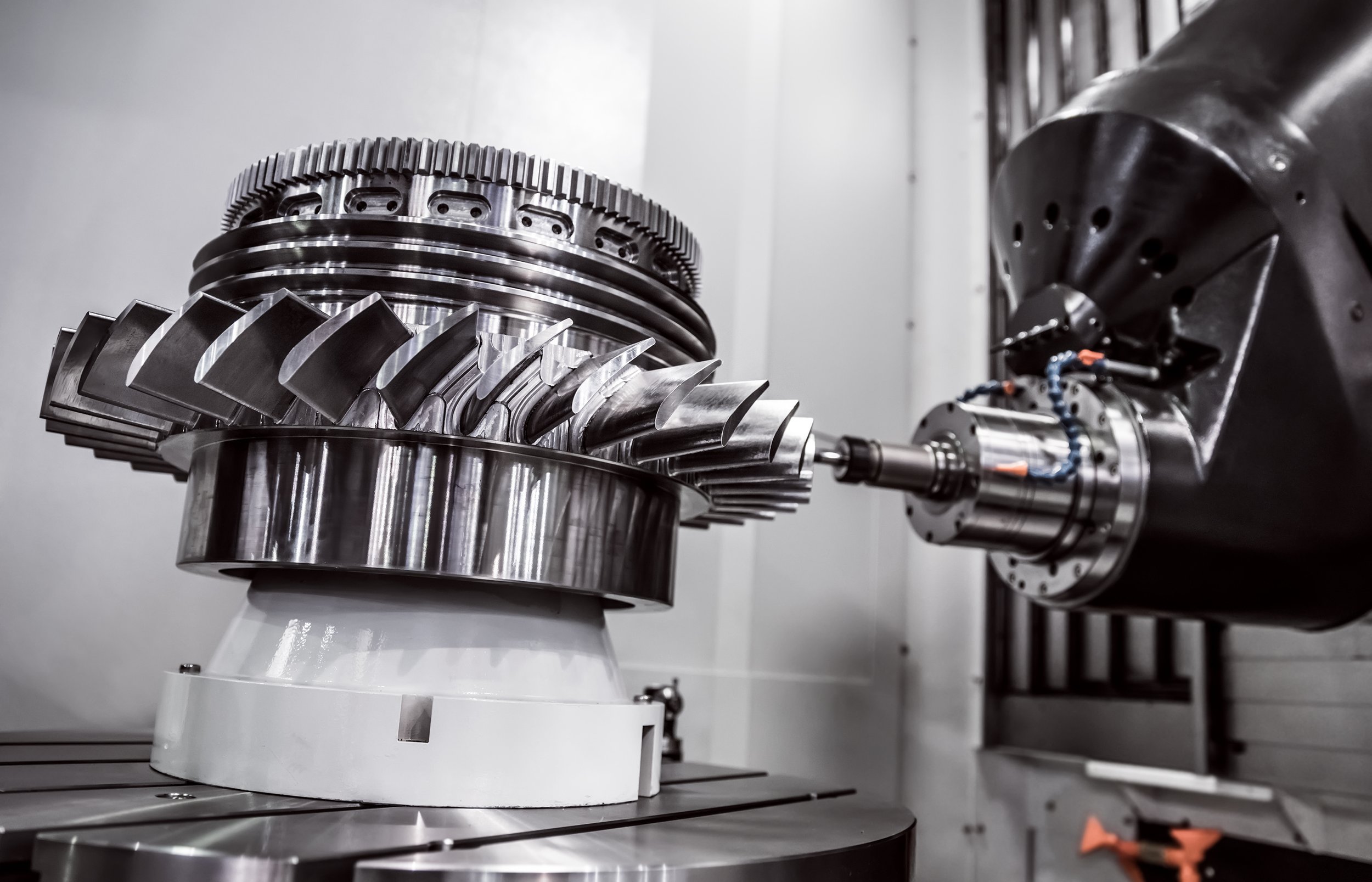

In the fastener industry, Tool-X® significantly boosts speeds and feeds and extends the lifespan of tools and dies. Our antimicrobial properties allow Tool-X® to extend the durability of coolants and oils, maintain cleaner sumps, and enhance pump pressures.

Tool-X®’s innovative self-cleaning technology diminishes microbial contamination along fluid flow lines and on sump surfaces, thereby promoting superior plant cleanliness and improved working conditions. Additionally, its contribution to reducing the chemical footprint marks a significant advancement for the fastener industry.

Utilizing material science (inert carbon nanoparticles) and advanced chemistry, we aim to minimize the chemical footprint and enhance the efficiency of existing technologies. This approach boosts machine output, extending the life of cutting tools and dies, and achieves these improvements without the need for re-tooling or capital investments.

Notice of Information

Tool-X Lowers Tool Cost

Eliminate or reduce the rotten egg odor caused by bacterial growth, achieving a "no stink effect."

Enhance the surface finish and roughness average (RA).

Decrease the frequency of changeovers, leading to fewer errors due to reduced human intervention.

Improve dimensional quality, minimize burrs, and enhance RA surface finishes.

Reduce the chemical footprint with fewer than 15 chemical components in Tool-X Water Base Coolant MP-101.

Achieve a return on investment (ROI) of up to 30% or more after the cost of Tool-X.

Tool-X Reduces Machine Overhead

Reduce cycle times and enhance throughput speeds and feeds by 10% to 30%+.

Extend thread rolling die life by 50% to 500%.

Enhance overall quality, lower rejection rates, and boost profits.

Tailor applications to decrease or eliminate the need for costly tool substrates and coatings.

Extend coolant life with Self-Cleaning Technology, which minimizes bacterial buildup and often eliminates the need for biocide additives with proper maintenance.

Improved Surface Finish

Where Tool-X® Is Used

Thread Rolling

CNC Machine

Swiss Screw

Milling

Drilling

Sawing

Cut-Off

Boring

Reaming

Tapping

Profiling

Turning Centers

Surface Grinding

Finish Grinding

Draw Box