Fastener Types

The term “fastener” encompasses a fairly broad category of tools, such as screws, nuts, and bolts, that share a common purpose: to mechanically hold objects together. With the exception of rivets, fasteners are typically non-permanent, meaning they can be disassembled and reassembled.

Vehicle assembly

Picture hanging

Building and construction

Furniture assembly

Cabinet installation

Electronics manufacturing

Screws are externally threaded fasteners and are often used for light-duty applications. Unlike a bolt, screws don’t require a nut to hold them in place. Typically, a pilot hole is drilled first before installing the screw. Thread forming screws are also available in cases where a pilot hole doesn’t exist.

Wood screws have coarse threads and a tapered head.

Deck screws are similar to wood screws but include self-tapping designs and corrosion resistance for outdoor applications.

Drywall screws feature a self-tapping head that can countersink without causing damage to drywall.

Sheet metal screws have sharper threads for connecting metal to other materials.

Machine screws have a uniform thickness and don’t taper off at the bottom.

Masonry screws have a flat tip and typically feature a hex-head design.

MDF screws can self-tap without splitting the material.

Watch our Screw Types video for a more in-depth look at screws!

Bolts are externally threaded fasteners most often used for heavy-duty applications and coupled with a washer and nut (referred to as an “assembly”) The bolt-nut-washer assembly work in tandem with each other to hold components together.

Carriage bolts have domed or countersunk heads with a square component under the heat to keep the bolt from moving while tightening the nut.

Flange bolts include a circular flange beneath the head for distributing loads evenly.

Plow bolts are for heavy-duty applications, such as heavy equipment, with non-protruding heads.

Hex-head bolts are six-sided with machine threads.

Square-head bolts have square heads, offering an easier grip for wrenches.

Allen bolts have a hexagonal socket for use with Allen wrenches.

Watch our Bolt Types video for a more in-depth look at bolts!

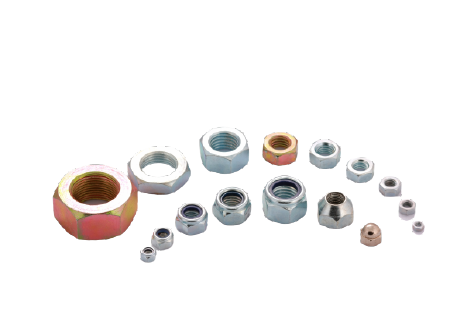

Nuts are fastening devices with a threaded hole, often used in conjunction with a bolt and washer to provide clamping force and prevent axial movement.

Hex nuts are the most common variety, featuring a hex shape and internal threads.

Flange nuts have a wide, serrated flange on one end that serves a similar function as a washer but without any added movement.

Coupling nuts are hex-shaped and join two male threads together.

Lock nuts include designs to prevent loosening due to vibrations.

Slotted nuts have sections cut out to create a locking mechanism with the help of a cotter ping.

Square nuts feature a square shape for greater surface area.

Wheel nuts are designed for securing wheels onto vehicles.

Wing nuts have pronounced tips or “wings” that are easy to grip and tighten with your fingers.

Nails are fasteners without any threads. Nails don’t have the same holding power as screws but have greater shear strength, which is preferred in some applications.

Common nails have a thicker shank for greater holding power for many different applications, but the thick head will be visible on most projects.

Box nails offer easier driving with a steel construction and diamond-point tip.

Brad nails can easily blend into wood trim.

Finishing nails are for more detailed work and have a small, flat head designed to blend in with project finishes, such as those on crown molding.

Drywall nails are designed for easy concealment and reduced slippage.

Flooring nails are designed for use with various flooring materials.

Framing nails can include a variety of styles, often designed for flush installation and easy concealment.

Roofing nails have a wide head and are often corrosion resistant.

Washers are often used in combination with a bolt and nut to distribute a fastener’s load.

Beveled washers add stability when attaching unparallel surfaces.

Flat washers are round and thin.

Lock washers use various mechanisms to prevent nuts, screws and bolts from vibrating loose.

Structural washers are thicker and used in heavy-duty applications.

Anchors are generally used to connect something to a material like drywall or concrete. The name comes from anchors used on a ship which embed in the sea floor to keep the ship from moving.

Internally threaded anchors

Externally threaded anchors

Masonry screw and pin anchors

Screw anchors

Hollow wall anchors

Sleeve anchors

Drive anchors

Rivets create a permanent joint between two objects. They are extremely durable in comparison to other types of fasteners.

Blind rivets, sometimes referred to as POP rivets, are used when there is no access to the rear (blind) side of a joint. They are installed with a tool that draws the mandrel through the body, creating a bulge and thus, a permanent seal.

Solid rivets have a solid shank and are installed by inserting the shank through a drilled hole and using a hammer or rivet gun, deforming the shank end to create a strong, permanent joint. Solid rivets are possibly the most widely used rivet, as they are used when safety and reliability are of utmost importance.

Semi-tubular rivets are similar to solid rivets, except have a shallow hole at the tip, opposite the head.

Split rivets are used to join soft materials, such as leather, wood, and plastics.

Drive rivets have a short mandrel that protrudes from the head. Once inserted into the drilled hole, the mandrel is struck with a hammer, setting the rivet and locking the mandrel inside the body of the rivet.

Rivet nuts, also known as threaded inserts, are internally threaded and installed similar to a blind or POP rivet. Used in thin material that does not allow for a tapped thread, rivet nuts are permanently installed in pre-drilled holes. Once installed, additional components can be attached using threaded fasteners.

There are many other types and variations of fasteners used all over the world for myriad purposes. No matter the application, the principle is the same: to join objects together. Each fastener type is used for a specific purpose based on its overall design, head type, drive type, thread type, and material. Secondary processes are also often done on many fasteners to improve their properties and functionality.

Keep an eye out and you’ll likely see fasteners in places you’ve never noticed before!